|

|

|||||||

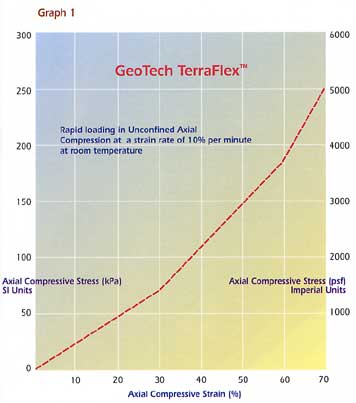

TerraFlex™ Elasticized Geofoam is also beneficial when rehabilitating or retrofitting existing structures by adding an increased safety factor against one or more geotechnical and/or structural failure mechanisms such as seismic forces and expansive soils and rock. When a compressible inclusion is required with a drainage component, you may use any commercially available drainage system which meets the project requirements. Other materials such as bales of hay or straw, wood chips, and cardboard have been used in compressible inclusion applications worldwide since the early 20th Century. However, these materials are unpredictable in their mechanical and physical behavior. Using TerraFlex™ Elasticized Geofoam will provide predictable and consistent

mechanical (stress-strain-time) behavior that is totally under the control

of the design engineer.

TerraFlex™ is unaffected by normally occurring weather at time of installation and will retain its physical properties under pre-engineered conditions of use. TerraFlex™ is made under a Quality Assured manufacturing process monitored by a third party laboratory. Size and Shape: TerraFlex™ is produced in block form and is easily fabricated to required dimensions for individual projects. The molded blocks have dimensions of 901.7 mm (35.5") x 1257.3 mm (49.5") x 4927.6 mm (194.0"). The blocks are then subjected to an additional manufacturing process of elasticization that increases the flexibility characteristics of the material. Environmentally Safe: TerraFlex™ contains no CFC's, HCFC's, HFC's, or formaldehyde. It is inert, non-nutritive and highly stable. It will not decompose, decay, or produce undesirable gases or leachates. TerraFlex™ is recyclable and safe for WTE Systems and landfills. Limitations and Cautions: TerraFlex™ stands up well to normal weather

conditions encountered during installation. Long-term (6 months or greater)

exposure to UV radiation will cause discoloration. Material should be

covered as soon as practical. Applicable Standards: TerraFlex™ is a proprietary product with physical properties that have been altered during the manufacturing process of elasticization. The parent material, TerraLite™, is manufactured with third-party (UL) certification to be in compliance with ASTM C 578 Type XI specifications. The block molding process of the parent material also includes additional voluntary, proprietary quality control standards and additives of GeoTech Systems Corporation.

**Protected under U.S. Patents No. 5,194,323 and No. 5,720,108. Other

U.S. and Foreign Patents Pending. 1997 AFM Corporation. Note: In the absence of data relating surface stress and deformation,

the designer can use deformations estimated using free-swell tests and

arbitrarily select a stress level for which the structure will be designed.

The required thickness of Geofoam is the calculated using the following equation:

Using this simple approach, different combinations of stress transmitted

to the structure and Geofoam thickness can be evaluated to find the most

cost effective design.

Using this simple approach, different combinations of stress transmitted

to the structure and Geofoam thickness can be evaluated to find the most

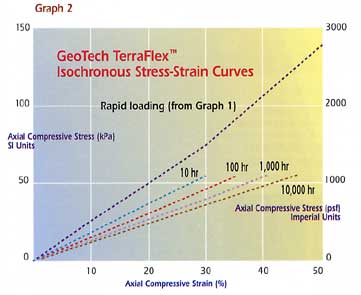

cost effective design.Graph 2 shows isochronous stress - strain curves for different durations of loading for TerraFlex™ Elasticized Geofoam. The stress-strain curves were developed using the results of unconfined axial compression creep tests. Installation: TerraFlex™ Elasticized Geofoam can be used in the following applications. Other engineered applications may also be appropriate.

For most applications the following guidelines apply. Additional guidelines for specific applications should be developed by the design engineer.

|

||||||||

NOTICE:

The information contained herein is, to the best of GeoTech's knowledge,

accurate and reliable as of August 1998. Freedom from patents of GeoTech

or others is not to be inferred. |

||||||||

| home | products | technical | solutions | |||

|

|

GeoTech

Systems Corporation |

|

|

Last Modified: September 25, 2018